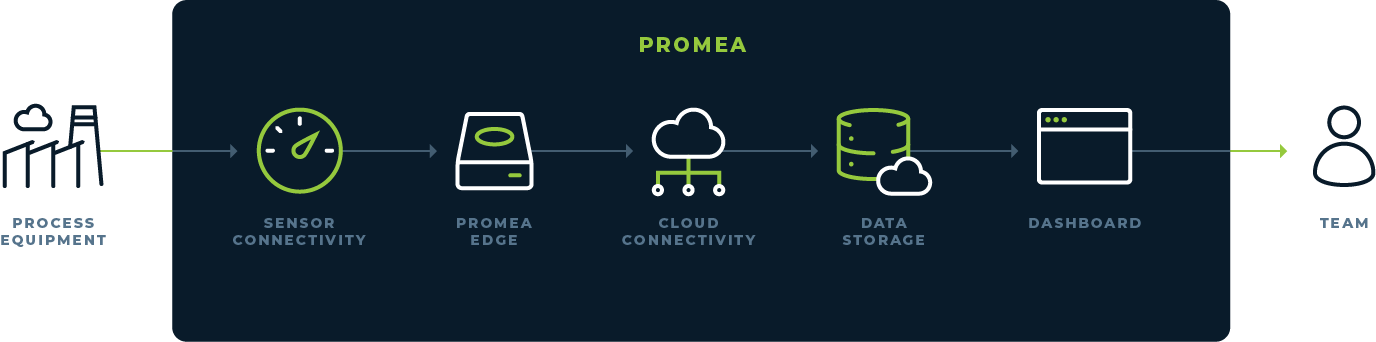

PROMEA

Step into Industry 4.0 with our transformational process measurement & analysis system.

Innovate 10x faster.

We help engineering teams make informed decisions faster by building, developing, and installing data automation systems that efficiently transform operations to Industry 4.0.

PROMEA is our all-inclusive process measurement & analysis solution for industrial manufacturing teams. This comprehensive, rapidly deployable system captures machine data and translates it into insights that optimize processes and solve engineering problems. Tell our team what data is needed on your dashboard, and we’ll handle the rest.

Where can PROMEA be leveraged?

PROMEA is an all-Inclusive industry 4.0 solution, collectively providing sensor connectivity, edge hardware, data storage, cloud management, and analytics dashboards in one comprehensive solution.

THE RESULT

10x faster, 10x leaner

Our outcomes are enabling teams to iterate 10x faster with less resource strain. By embracing automation and leveraging the robust capabilities of our team, you can compete with the industry’s biggest players, without growing your headcount.

1. COLLECT DATA

Forget indicators and anecdotal paper notes. We utilize digital sensors to autonomously capture data with more accuracy and more consistency.

2. STORE DATA

By automatically storing data on secure databases, production info is instantly accessible from anywhere. No spreadsheet versions, no data silos, and no thumb drives.

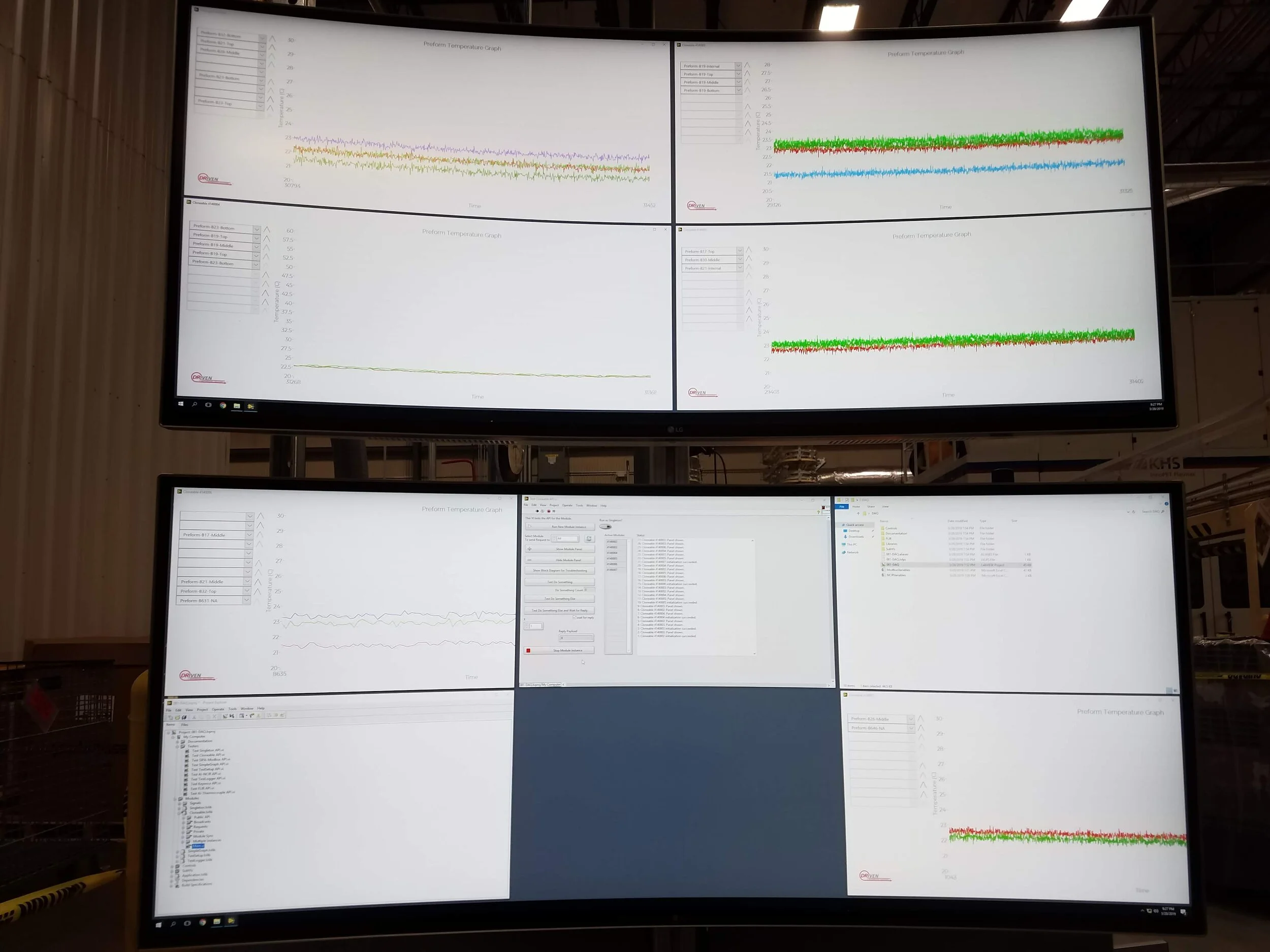

3. ANALYZE & VISUALIZE

With custom automated dashboards, teams can observe real trends in real-time, revealing process insights that typically don’t surface in manual analyses or paper report snapshots.

4. DECIDE

With insights that are current, accurate, and clear, teams spend less time working through subjective opinions and more time planning iteration updates, ultimately solving problems faster.

Lean on Novum.

Curious how PROMEA will impact your current team structure? Here are the things you won’t need when partnering with us:

x Data Engineers

x IT Analysts

x Software Developers

x PLC Programmers

x Electricians

x Paper

x Revision Control

x Avoidable Errors

x Unnecessary Emails

How is PROMEA commonly used?

Recent Applications

Customer Testimonials

FAQs

-

While timing is application dependent, the majority of PROMEA systems can be built, installed, integrated, and running in 5-7 days. Typically, Novum quotes 4-6 weeks due to current supply chain constraints.

-

Based on the application and questionnaire information, Novum provides a fixed-price or leasing quotation within a matter of days.

-

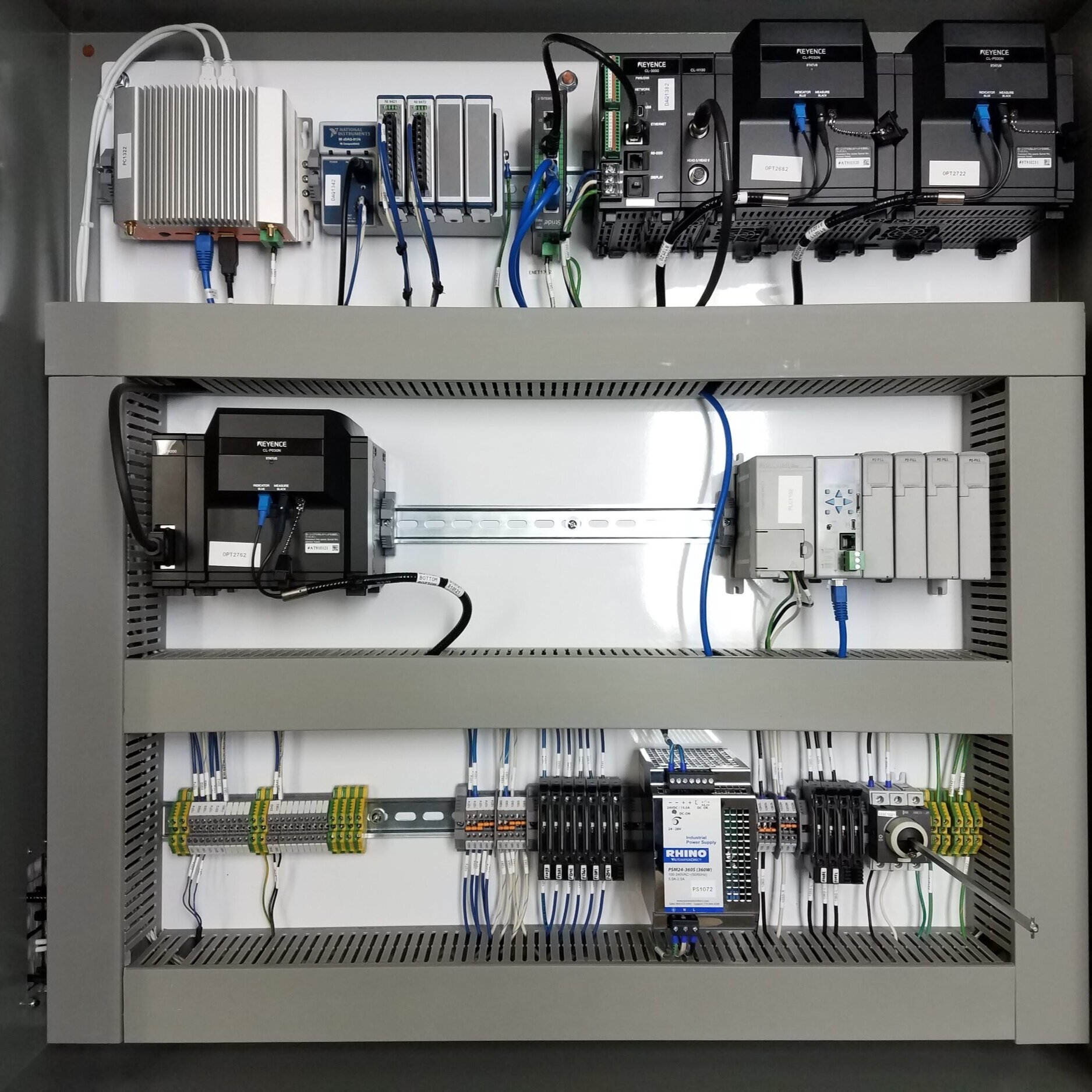

We typically utilize a Secure Cellular Router to push data to the cloud from PROMEA without requiring a connection to the company network. It’s as “dangerous” as having a smartphone within the facility, so most IT groups allow this.

-

The PROMEA Edge controller typically requires 120 VAC x 60 Hz x 5 Amps. Additional current may be required based on the number of field sensors/connections of the application. PROMEA can also be solar-powered for remote field installations.

-

Novum utilizes cloud technology that maintains the highest security standards. We most typically utilize Amazon Web Services (Lightsail & RDS) for our SQL Databases.

-

Process Measurement & Analysis

-

Yes, we provide trial systems which is decided on a case-by-case basis depending on process measurement complexity, installation location, and long-term project potential. Contact Novum to request a trial for your application.

-

Yes, Novum offers a full-line of Industrial Automation support services including electrical panel upgrades, PLC programming, and machine retrofits.

-

The Promea Edge controller is designed to operate within -10 to 140 Fahrenheit temperatures, with IP65 rating. Optional Stainless Steel or IP69 washdown ratings are available upon request.

-

Yes, we allow private labeling of PROMEA for an additional fee.

-

We typically utilize industrial bus IO blocks to efficiently connect sensor/machine wiring back to the PROMEA Edge controller. When large distances are required we typically use an industrial Wireless Ethernet module (Sure Cross from Banner Engineering) to transmit data up to 2-3 miles.

-

Our standard PROMEA Edge Controller can sample up to 200 Hz while our High-Speed PROMEA Edge can sample up to 1 MHz (utilizing FPGA hardware). Typically, the PROMEA Edge Controller performs various analytics before pushing aggregate data to the cloud.

-

Novum is hardware agnostic. We choose the best hardware for the application. With that being said, PROMEA Edge typically utilizes a Rugged Industrial PC and a PLC/DAQ device, along with all supplementary components (circuit breakers, power supplies, etc.).

Request a Quote

Empower your process, quality, and production engineers today.